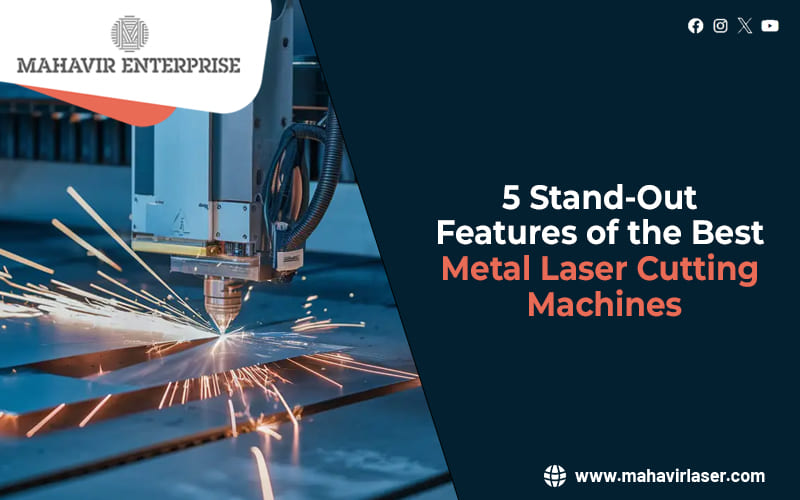

Metal laser cutting machines have brought in a new wave of precision and swift cutting at a very reasonable price bracket. Whether it is the automotive industry, aerospace industry, or a simple metal cutting company, all of them prefer using the new-age laser cutting as their method of cutting. It offers precision, perfect fitting, accuracy, speed, and cost-efficiency. When purchasing a laser cutting machine, there are a few features that you must check. In this blog, we will enumerate the top 5 features of the best metal laser cutting machine.

How Does a Laser Cutting Machine Work?

The metal laser cutting machine uses a high-power laser to precisely cut through metal materials. The laser generated is either created through stimulated emission in a gas medium or through fiber optics. The laser beam is concentrated to a fine, high-energy point using a focusing lens.

These features offer immense precision in cutting, reduced energy and material loss, create less waste, and make perfectly fitting counterparts. Mahavir Enterprise is a leading provider of laser cutting service in Vadodara. Our team of experts and professional laser cutting machine operators customise and refine your order based on your demands. We use advanced softwares like CAD to boost productivity and efficiency.

Top 5 Features of Laser Cutting Machines

- Laser Resonator: The laser resonator produces a beam using a doped fiber in fiber lasers or a gas mix in a CO2 laser. It defines the beam quality, power, and stability by amplifying light within an optical cavity.

- CNC Control Unit: Serving as the brain of a CNC control unit, it controls the movement of the laser beam and its workability. It offers precision, repeatability, and efficiency through programmable software and automation integration.

- Cutting Head: The cutting head is responsible for concentrating the laser at a narrow spot to precisely cut through the metal. Some advanced cutting heads also include height sensors and autofocus capabilities.

- Gas Delivery System: The metal cutter head also has a high-pressure jet to deliver gases like oxygen, nitrogen, or compressed air. The gas assists in expelling molten metal from the cut area and enhances the cutting speed and quality.

- Optical Delivery System: It consists of mirrors, lenses, and fiber optics that guide and amplify the laser beam. A high-quality beam can be generated by these high-quality optics.

Different Types of Laser Cutters

- Beam Generation: In this type of laser cutter, the beam is either generated by fiber optics or by gas emission (CO2). Fiber lasers offer premium beam quality, efficiency, and durability.

- Beam Amplification: In this type, the laser beam is amplified within a doped fiber and precisely delivered through fiber optics and ensuring minimal energy loss, consistent beam quality, and accurate delivery.

- Beam Focusing: The laser beam is concentrated to a fine, high-energy point using a precision focusing lens or optical system. This provides a clean, accurate, and high-speed cutting.

Conclusion

The laser cutting machine is a great innovation for metal fabrication companies. It is faster, offers precise solutions, saves energy, generates less waste, produces superior quality cuttings, and provides operational flexibility. Mahavir Enterprise is one such trusted provider of CNC laser cutting service in Vadodara. We work efficiently through versatile metals and intricate designs. Our laser cutting team comprises trained and certified operators who understand the machine and work efficiently through complicated orders. Want to place an order? Give us a call to discuss.

Also Read: Advantages & Disadvantages Of Plasma Cutting