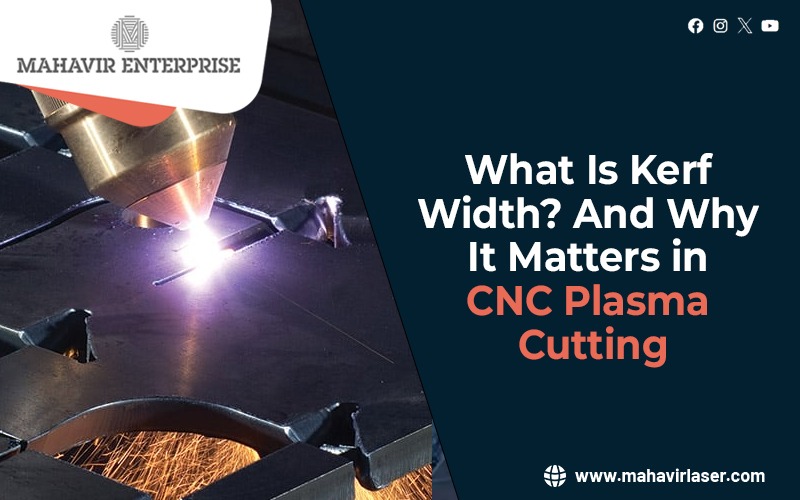

CNC plasma cutting is considered one of the most precise cutting techniques for metallic sheets. It gained its reputation due to its small kerf width, which offers a more accurate design and less resource loss. Kerf width is a crucial aspect of all types of CNC cutting, such as CNC laser cutting, CNC plasma cutting, oxy-fuel, and CNC waterjet cutting. In this blog, we will understand what exactly a kerf width is and why it is so important.

What Is a Kerf Width?

A kerf width is the width of the cut made by the cutting medium, like laser, waterjet, plasma, etc. When these things interact with the material, they remove a part of the material while making the desired cut. This is known as kerf width. CNC plasma cutting uses an extremely hot plasma, or ionized gas, at a high velocity to melt the metal and remove it to make the design. There are several factors that influence the width of the plasma arc generated during the plasma cutting method. It includes the power level, the speed of the cutter, and the thickness and composition of the material.

However, the kerf width created by the plasma is comparatively narrow, typically ranging from 0.1 mm to 1.5 mm. It is important to note that every material has a unique kerf. At Mahavir Enterprise, we develop an accurate kerf compensation for each material. As the leading providers of plasma cutting services Vadodara, we cater to a large group of skilled professionals and modern-day cutting equipment backed by advanced software like CAD. We strive to provide the finest services to our customers and tailor our products to meet their specific needs. Call us to discuss your needs.

Why Is Kerf Width Important?

Kerf is an important aspect of plasma cutting because it determines the precision, effectiveness, and cleanliness of the cuts made. The gaps left by the plasma after cutting through a material are known as a kerf. Not considering these gaps may lead to irregular cutting and cause trouble in the assembly stage. A large kerf leads to losing a lot of material. It also affects the overall quality of cut edges, affecting multiple pieces, and can significantly affect how the pieces fit together.

Also Read: 3 Main Type of Lasers for Cutting & Brass CNC Cutting Service

How to Manage Kerf Width?

Kerf width is different for all materials. Each cutting removes a different amount of material. Processes like waterjet, plasma, and laser cutting make a narrower kerf compared to others. In the case of plasma, kerf is affected by nozzle size, current amount, torch height, and gas settings. Kerf was traditionally managed manually by operators; however, in modern cutting systems, the controls have access to the kerf values, and operators do not need to manually look them up each time. The operator now needs to simply feed the material types, and the machine itself adjusts the kerf width. The assistance of modern technology helps in faster processing and more accurate cuttings without wasting raw materials.

Conclusion

CNC plasma cutting has numerous benefits and manageable cons. Kerf width is a critical aspect of any cutting and can affect many factors, such as accuracy and precision. Kerf might seem like a big issue, but it is fixable with the help of advanced software and automation. Choose Mahavir Enterprise for the finest CNC plasma cutting services in Vadodara. We use advanced tools, machines, and modern-day automation and AI software to ensure the smoothest cut edges and perfectly fitting pieces. Call us to discuss your order.

Also Read: What is CNC Plasma Cutting?