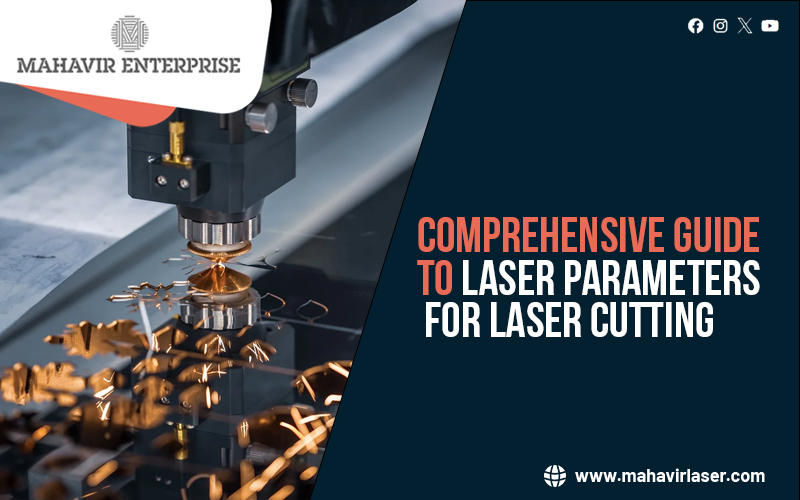

Laser cutting is a reliable fabrication and cutting method to make precise cuts and intricate patterns with a powerful laser. This process cuts or engraves materials by vapourizing the targeted portions of the materials. Laser cutting parameters like power, speed, lens focal length, nozzle shapes and other laser parameters define the behaviour of the laser. In this blog, we discuss the ideal laser parameters for laser cutting for high-quality cutting results.

What are the Different Laser Cutting Parameters?

To achieve precise, high-quality cutting results, it is crucial to understand the different laser parameters. The laser cutting metal service relies on laser cutting settings for an efficient and accurate cutting process that impacts material compatibility, operational speed, power and other aspects.

5 Laser Parameters for Laser Cutting

Laser Power

Laser power refers to the energy released from the laser per second, measured in kilowatts (kW). This is an important laser cutting setting as it dictates how much energy goes into the cutting process for different materials and thicknesses. For instance, when it comes to the main parameter for stainless steel laser cutting, a 1kW laser power can effectively cut through up to 5mm of stainless steel. A 3 kW laser power can cut 12mm of the same material, offering better versatility.

Cutting Speed

Cutting speed is measured in meters per minute (m/min). The laser cutting speed should be adjusted as per the material’s thickness and required cut quality. Proper cutting speed allows the laser to cut through materials precisely and reduces the risk of melting or burning edges.

Wavelength

Wavelength is recorded in nanometers (nm), referring to the colour of the light emitted from the laser. It determines the laser’s ability to interact with different materials. Wavelength selection can improve the cutting process for different materials. Shorter wavelengths are ideal for cutting industrial metals, and longer wavelengths are better for composite materials or non-metals.

Pulse Duration/Width

This laser parameter is measured in microseconds or nanoseconds. Pulse duration or width should be accurately adjusted to align with the materials’ properties and required results. Short pulse durations are used for detailed, precise work and delicate materials to reduce heat damage. Longer pulse durations are essential for deeper cuts or working with thicker and tougher materials.

Nozzle Diameter

he nozzle diameter impacts the precision and characteristics of the laser beam. A smaller nozzle provides a more concentrated and focused beam that is perfect for sharp-clean cuts. While a larger diameter provides a wider diameter is suitable for thicker materials.

Adjusting laser parameters enhances the precision and quality of cuts, boosts operational efficiency & prolongs the service life of laser cutting equipment.

Want to get laser cutting job work in Vadodara done? Mahavir Enterprise offers a comprehensive range of CNC cutting and laser cutting services for all your fabrication and manufacturing requirements. For the best quotes, call us.